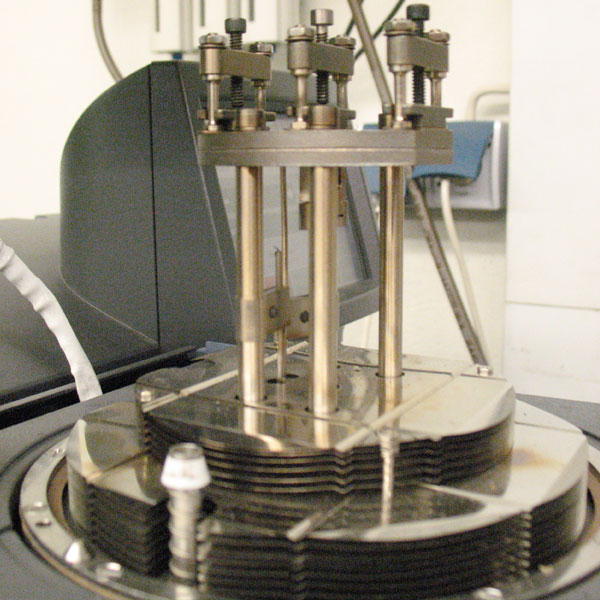

Mechanical standard tests

Mechanical standard tests

- 7 servo hydraulic test machines for static and fatigue tests

- Latest Zwick / Roell control system

- Hydraulic clamping of specimen

- 2 Zwick test machines for static tests (60 kN and 100 kN)

- 140 m² test area

- Hot / wet, high and -80 °C low temperature tests

- Conditioning chambers for wet ageing

- Mobile conditioning aggregate

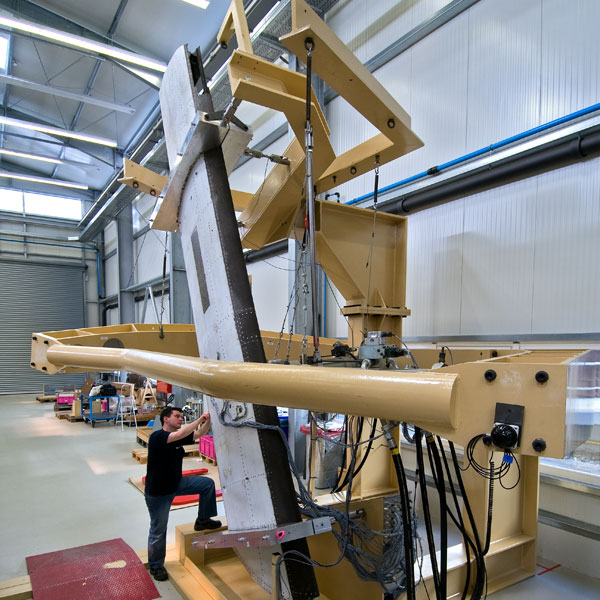

Test fields

Test fields

- 400 m² test field area to accommodate tests in own rigs

- Strong floor I: 8.4 x 5 m (extendable to 8.4 x 12 m), single load up to 1000 kN

- Strong floor II: 5.4 x 5.4 m, single loads up to 3200 kN

- Tower: Max. specimen length 3.5 m, loads up to 3200 kN

- 40 servo-hydraulic actuators from 10 kN to 3200 kN

- Schenck Labtronik 8800 System

Laboratory

Premium AEROTEC is highly experienced in structural testing.

Laboratory for composites and chemistry

- 160 m² test area

- Thermal, chemical and optical testing for composites, metals,paints and varnishes

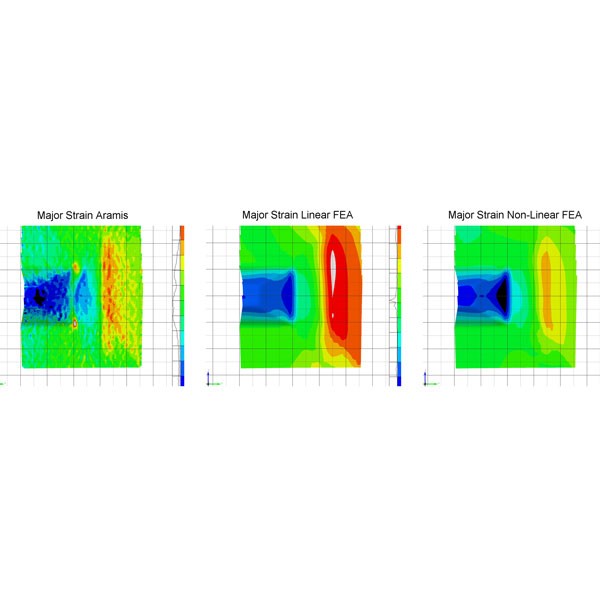

Structure

tests

tests

Strong support for structure tests

- ARAMIS: Digital image correlation in mechanical testing

- intellifast: Ultrasonic measurement of fastener pre-load

- Ultrasonic testing via A-scan and phased array (Omniscan, Rotoarray)

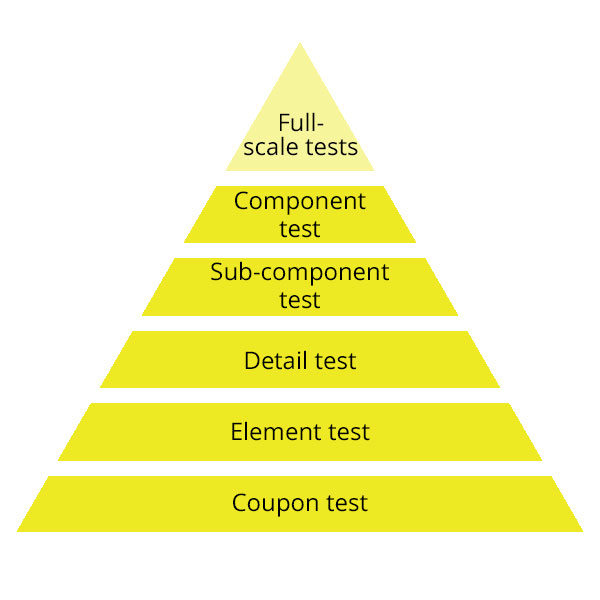

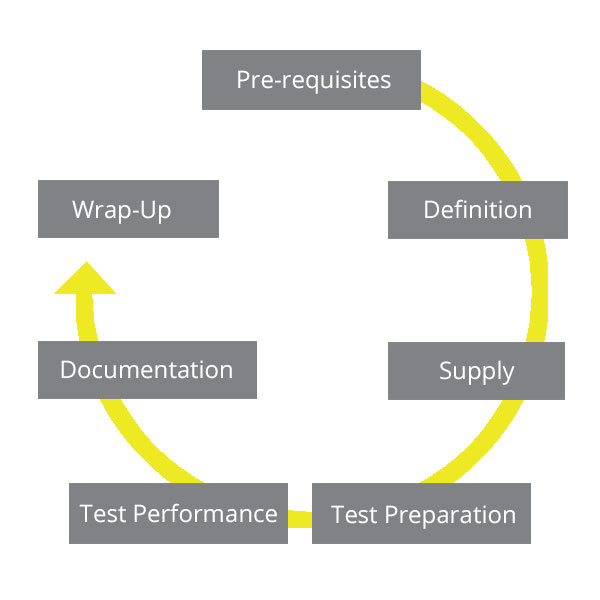

Test cycle process - Seven steps to success

Premium AEROTEC operates a highly sophisticated and modern equipped test laboratory that offers you an “all-round care-free package” for your testing needs.

We combine decades of experience in mechanical, thermal, optical, chemical testing with certified state-of-the-art competences and expertise along the entire process chain.

Premium AEROTEC is your ideal partner for:

- non-standard structure tests

- standard composite tests

- quality examinations for parts including extensive fatigue testing

Contact

Do you have any enquiries concerning testing?

Please direct all questions to our sales team:

Roberto Mazzella

Phone + 49 (0) 821 801 63714