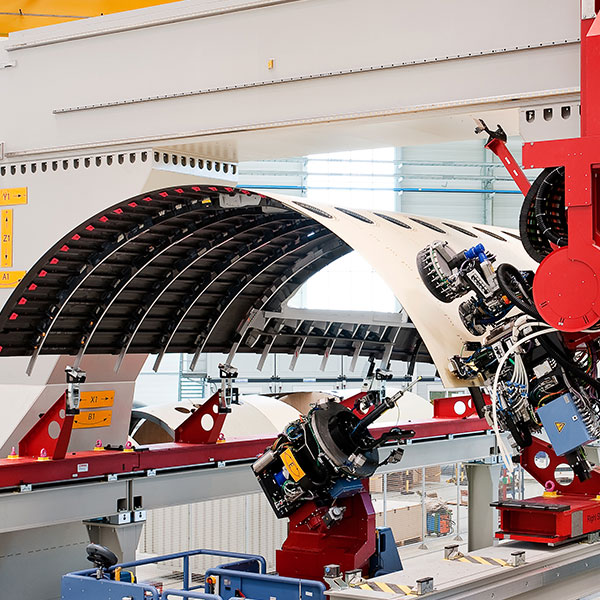

Made by Premium AEROTEC

Premium AEROTEC is the world leader in the production of large and complex shaped aircraft components. Its product portfolio includes complete fuselage sections, floor structures, wing components, loading doors and pressure bulkheads. Thanks to the symbiosis of a wealth of ideas, sound development and the expertise of its staff, the company is able to break new ground in the processing of high-tech materials which meet the most demanding quality requirements. The world’s biggest aircraft manufacturers rely on products made by Premium AEROTEC.

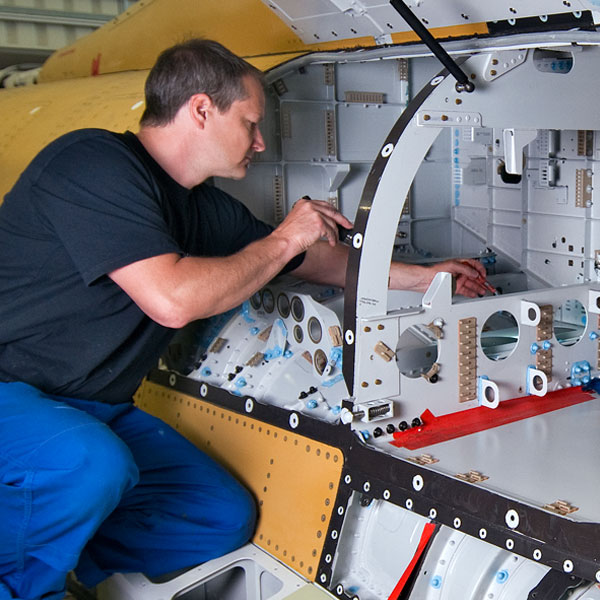

Maintenance

Premium AEROTEC can avail itself of a broad range of skills in the maintenance and repair of aircraft components. For this, the company is able to draw on experience in development and production spanning decades and to combine this with the state-of-the art process capabilities. This enables Premium AEROTEC to support its products throughout their entire life cycle and to supply its customers with products which are ready for immediate use.

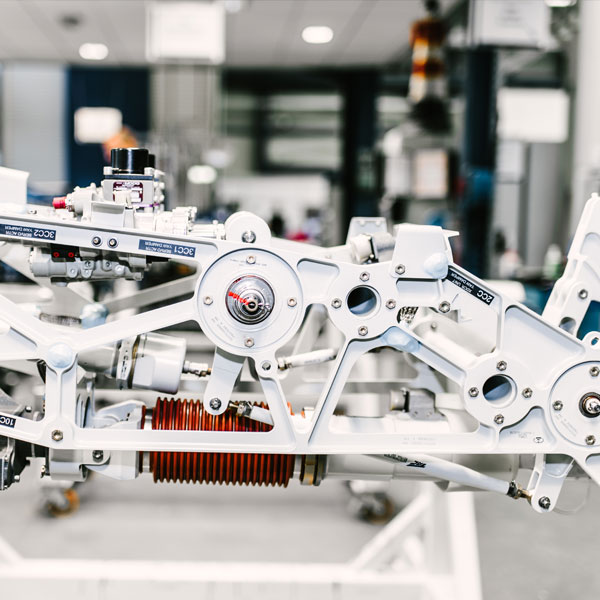

Structural testing

Premium AEROTEC operates an extremely well equipped, state-of-the-art testing laboratory for a wide range of tests. Its range includes mechanical tests for components made of metal or composite materials, as well as thermal, optical and chemical tests. The laboratory is certified to the current globally recognised standards. This makes Premium AEROTEC the ideal partner for large structural tests, mechanical standard testing for composites and for tests to demonstrate the service life of a material or component.

The contact person for our products:

Roberto Mazzella

Head of Sales, Aftersales & Marketing