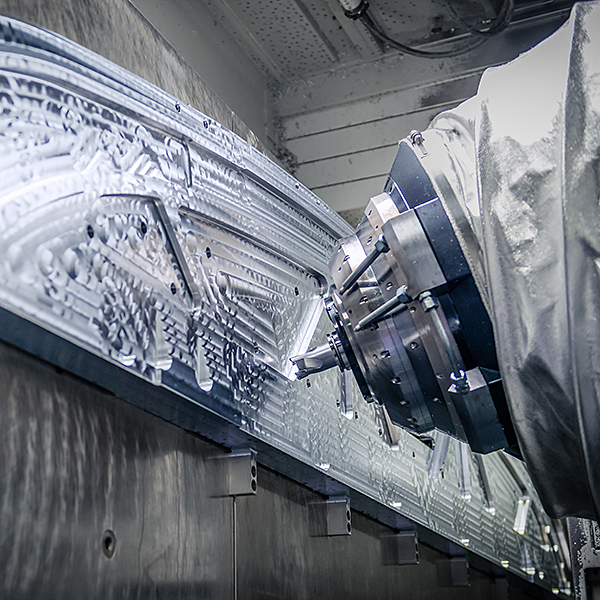

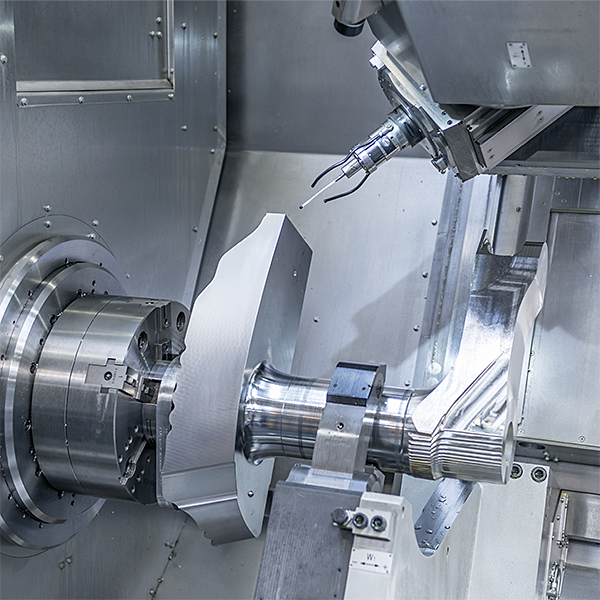

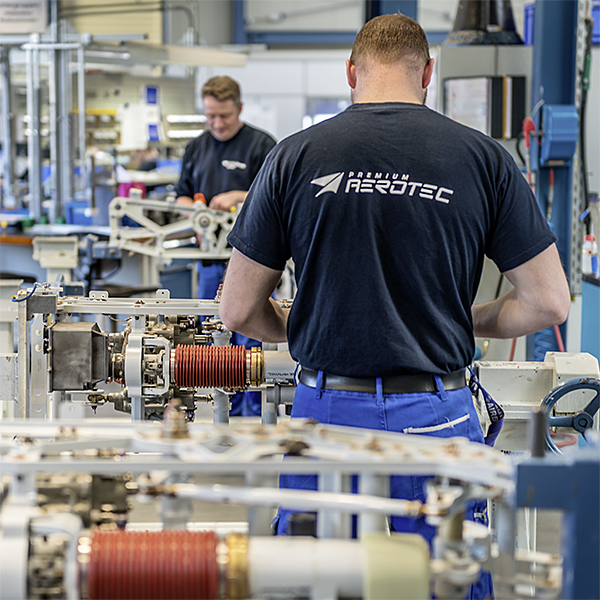

Premium AEROTEC is a leader in the field of high performance cutting. In manufacturing aircraft components from aluminium and titanium, the company is able to avail itself of one of the most high-performance fleets of machinery in the world. The modern five-axis processing centre enables the company to manufacture aluminium fuselage frames of up to seven metres in length.

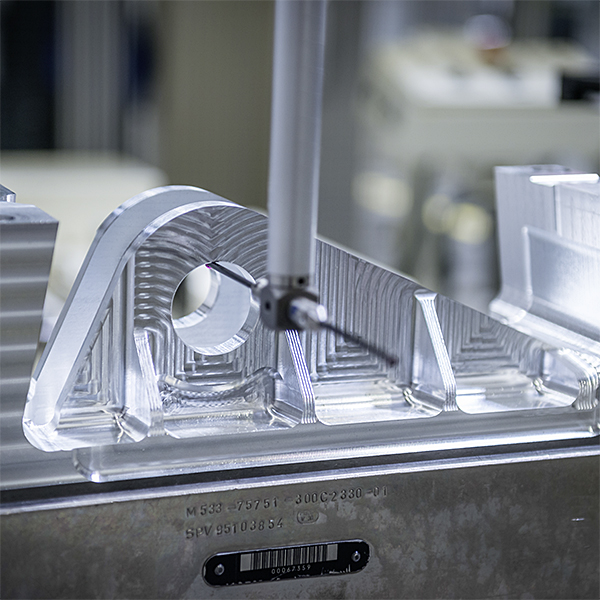

The programming tools are state-of-the-art and also incorporate highly developed simulation options. This facilitates optimal transfer of the construction data to the NC programmes. Premium AEROTEC’s comprehensive experience feeds into the development of the cutting tools. This allows the processes to be calibrated to meet the most stringent requirements and enables outstanding results. Integrated closed loop data management systems ensure complete coverage of the value creation chain and its seamless integration into big data and industry 4.0.