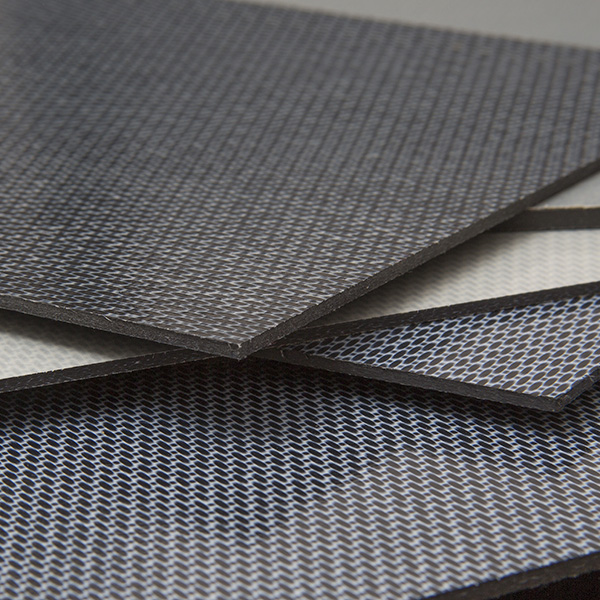

In the field of aircraft construction, Premium AEROTEC is one of the biggest innovators in the use of the material CFRP. For this, the company leverages its experience in the processing of carbon fibre composites gained over four decades. Premium AEROTEC is able to make use of a wide range of processes that have been tried and tested in practical use, and is thus able to exploit the full potential of this material.

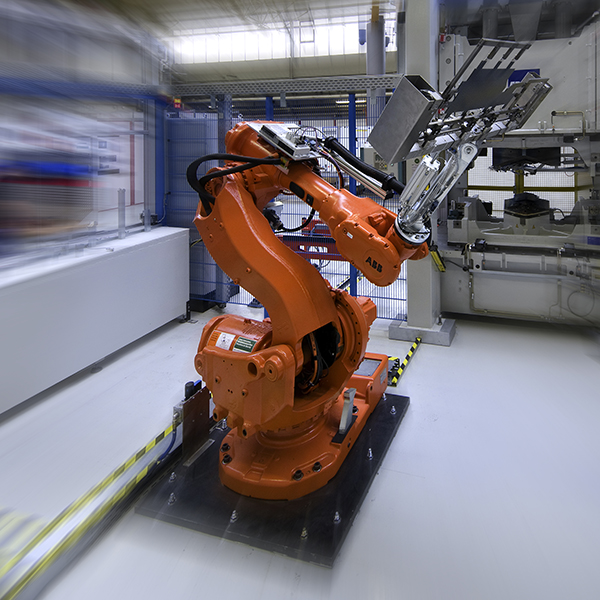

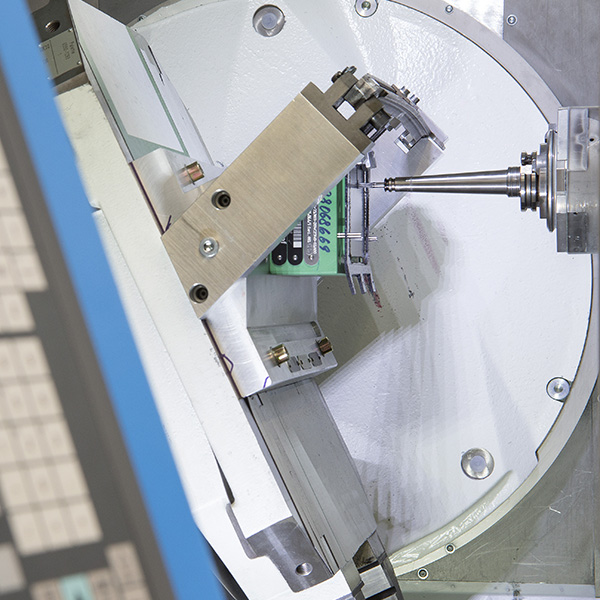

The AFP process (Automated Fibre Placement) is characterised by the precise placement of pre-impregnated CFRP strips by robots. Premium AEROTEC uses this process in manufacturing pressure bulkheads and fuselage shells of up to 17 metres in length. The company is able to draw on extensive skills in product and technology development for this. It is this foundation that made transferring the AFP process to the highly complex door frame structure possible. Instead of the standard titanium frames, significantly lighter CFRP door frames can now be used for the A350 XWB.

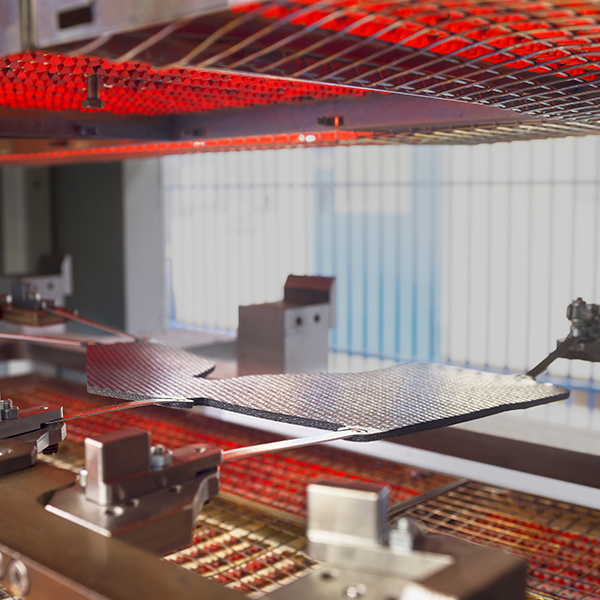

Our thermoplastic components are also used extensively in the aircraft. Premium AEROTEC particularly relies on this technology for clips and brackets. The company has largely automated this process and is continuously developing it for future applications in aviation. Other products such as the upper cargo bay door of the A400M use our patented VAP® process (Vacuum Assisted Process). In this, the previously shaped fibre meshes are infiltrated with resin in a vacuum and then hardened by means of heating. This process is also used by Premium AEROTEC in the manufacture of pressure bulkheads.